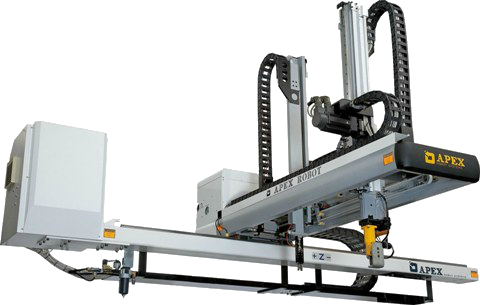

SH-DM SERIES

3 / 5 AXES SERVOMOTOR

DRIVENCNC ROBOTS

WITH TELESCOPIC ARM

OVERVIEW

3 / 5 AXES SERVOMOTOR DRIVEN CNC ROBOTS WITH TELESCOPIC ARM

Rigid box frame design on the cross axis. Very sturdy under high speeds operation. Strong and lightweight Aluminum alloy extrusion material that can absorb shock wave further more to reduce vibration.

3/5 axes synchronized movement. Free tracking control with pulse generator, easy to program. Sub-arm model equipped with electrical motor for easy strokes adjustment. No need to climb up.

STANDARD 14 SPARE INPUTS AND 12 SPARE OUTPUTS FOR INTERFACING WITH OTHER ANCILLARY EQUIPMENT. EXTENSION UP TO 30 I/O ALSO AVAILABLE.

PARTS REMOVAL:

- 3 axes synchronized movements reduce complexity and cost to buildend-arm-tooling.

- Able to reach parts with hooks and undercuts using unconventional paths such as curves, etc.

STACK AND ARRAY:

Each cycle can handle up to 9 stack areas with individual stack formats. Can also place parts onto 100 points on the same surface.

INSERT AND GRID:

Each cycle can place 9 different insertion materials into the mould, fed from a single point, grid pallet, or multi-station.

3D PATH:

The robot can follow teaching point-to-point path to move. It lets the track move smoothly and shorten the cycle time.

INSPECTION:

- Reject program: Detects signal from the moulding machine, set the reject part count and places part in different area.

- Inspection program: Places part in different area for QC inspection, for exampleevery 100 cycles.

- Test-mould program: Allows checking of parts at the beginning of each automatic moulding cycle before cycle counter starts.

- Weight program: Checks part quality from electronic weigh scale and separates defect parts.

Model

NO. |

Stroke

(mm) |

Max.

Payload (kgs) |

Net

Weight (kgs) |

Operating Air Pressure |

|||||

Crosswise(kick) |

Vertical |

Traverse |

|||||||

Main(E) |

Sub |

Main(C) |

Sub |

(I) |

|||||

SH800D |

Telescopic & Single-Arm |

520 |

- |

800 |

- |

1320 |

6 |

400 |

5 kg/cm2 |

SH1000D |

Telescopic & Single-Arm |

700 |

- |

1000 |

- |

1560 |

6 |

425 |

|

SH1200D |

Telescopic & Single-Arm |

940 |

- |

1200 |

- |

1800 |

12 |

475 |

|

SH1400D |

Telescopic

& Single-Arm |

1060 |

- |

1400 |

- |

2020 |

12 |

500 |

|

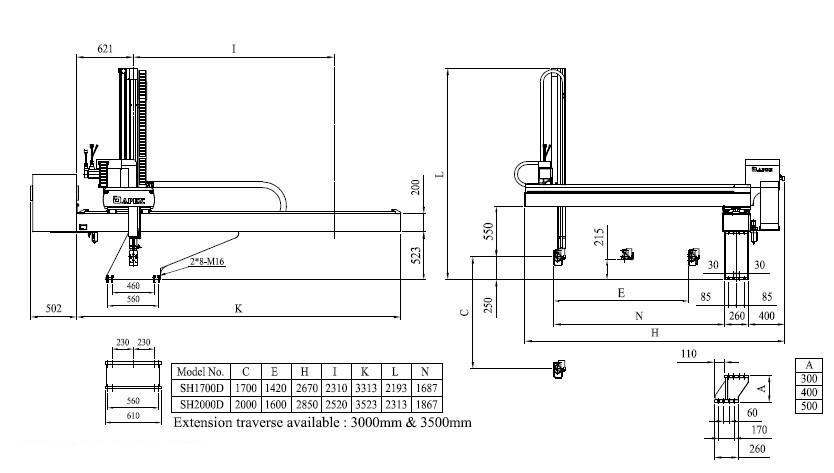

SH1700D |

Telescopic

& Single-Arm |

1420 |

- |

1700 |

- |

2310 |

30 |

890 |

|

SH2000D |

Telescopic

& Single-Arm |

1600 |

- |

2000 |

- |

2520 |

30 |

920 |

|

SH800DM |

Telescopic & Double-Arm |

395 |

395 |

800 |

850 |

1320 |

6 |

425 |

|

SH1000DM |

Telescopic & Double-Arm |

575 |

575 |

1000 |

1050 |

1560 |

6 |

450 |

|

SH1200DM |

Telescopic & Double-Arm |

775 |

775 |

1200 |

1250 |

1800 |

12 |

500 |

|

SH1400DM |

Telescopic & Double-Arm |

895 |

895 |

1400 |

1450 |

2020 |

12 |

525 |

|

SH1700DM |

Telescopic & Double-Arm |

1270 |

1270 |

1700 |

1750 |

2310 |

30 |

920 |

|

SH2000DM |

Telescopic & Double-Arm |

1450 |

1450 |

2000 |

2050 |

2520 |

30 |

950 |

|